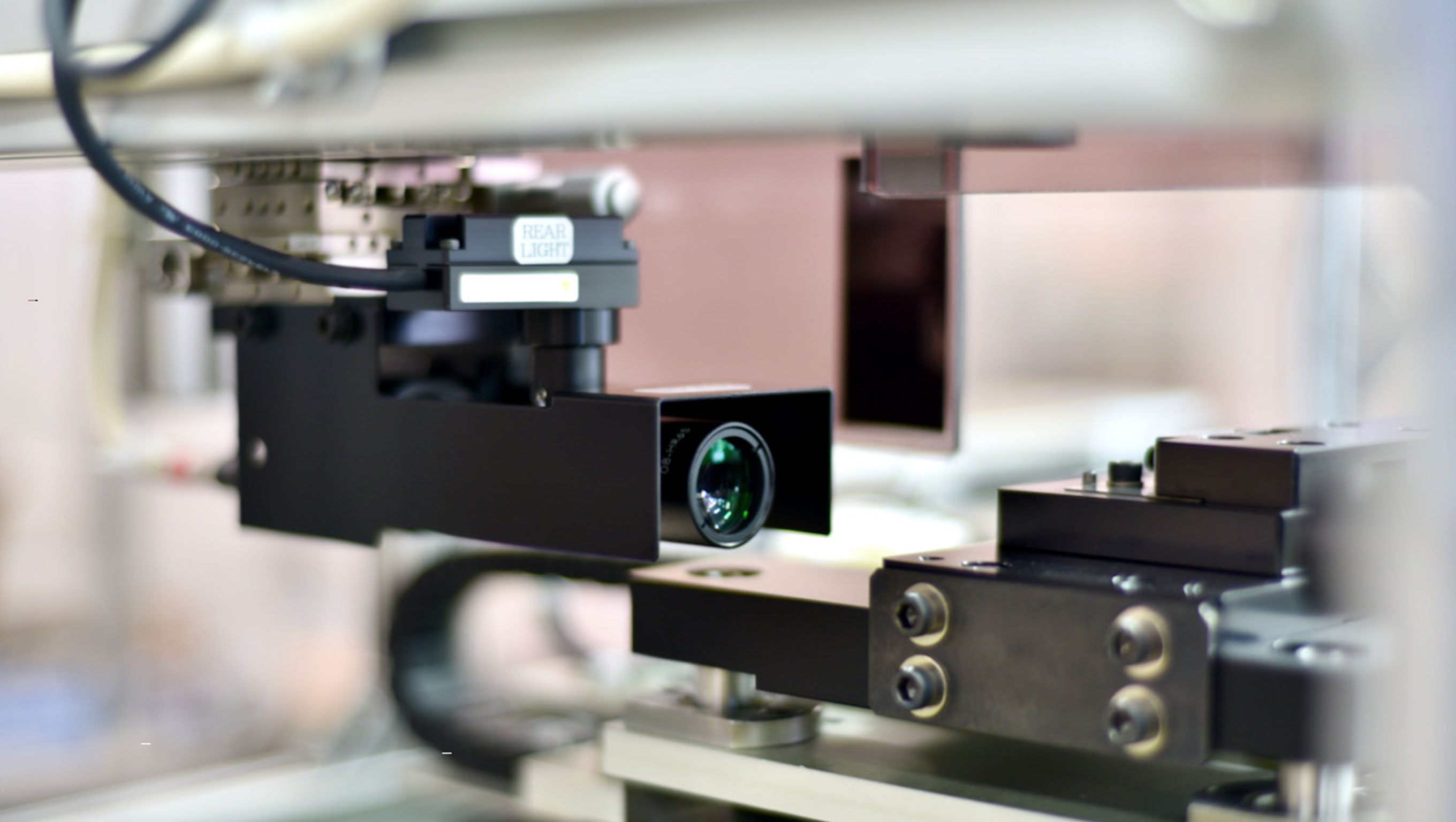

100% Quality Inspection

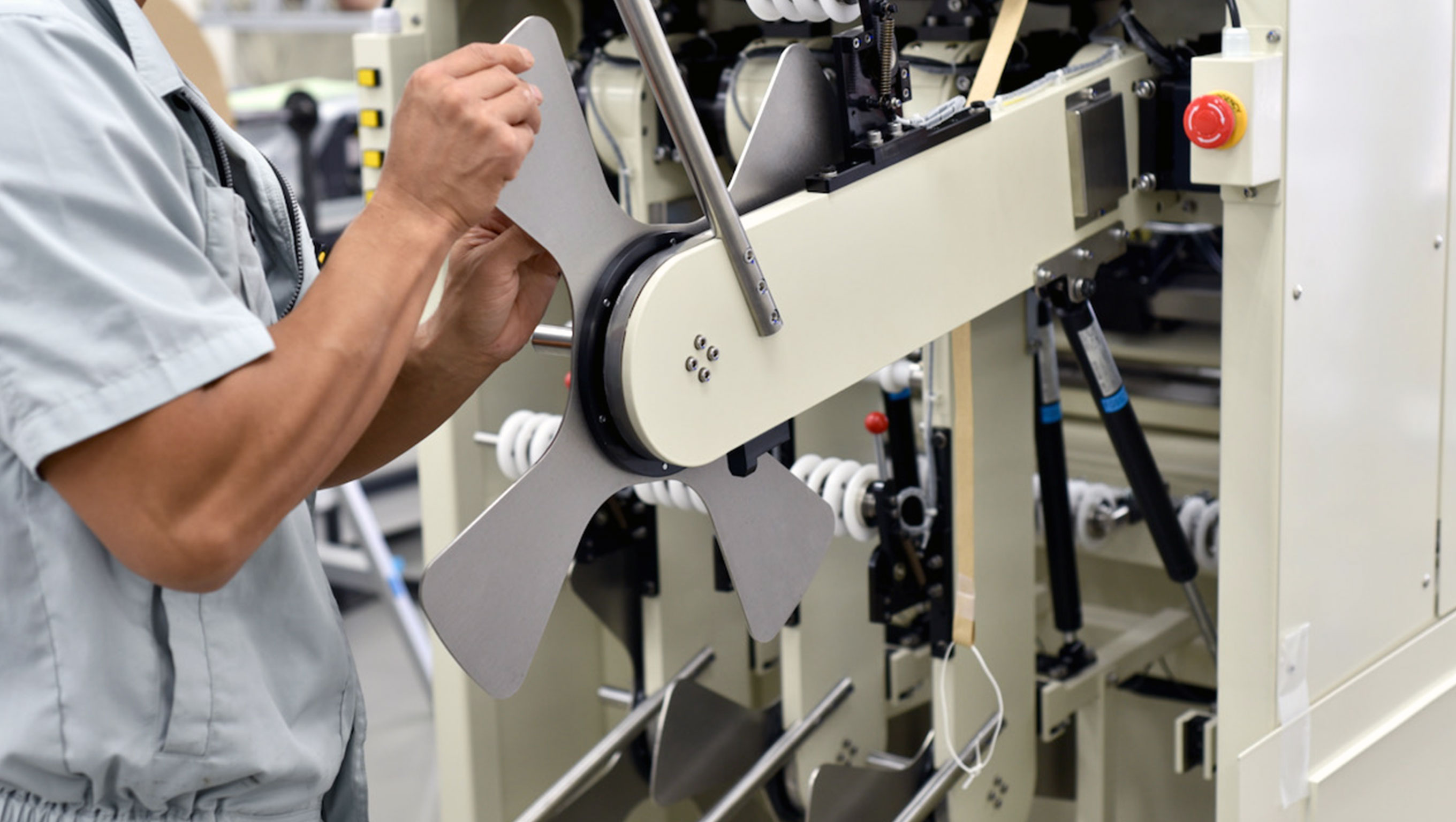

Constantly Challenge New Technologies and Contribute

to The Development of Society

We have provided unique sensors that meet the needs of various industries and research institutions, such as industrial equipment and research fields.We will introduce some examples of our product introduction, though it is part of this.