Requesting Main Industry : Manufacture of automotive harnesses

The Cross-Sectional Sample Preparation Efficiency of Crimping Terminals should and the Crimping Quality should be improved

Problems we had

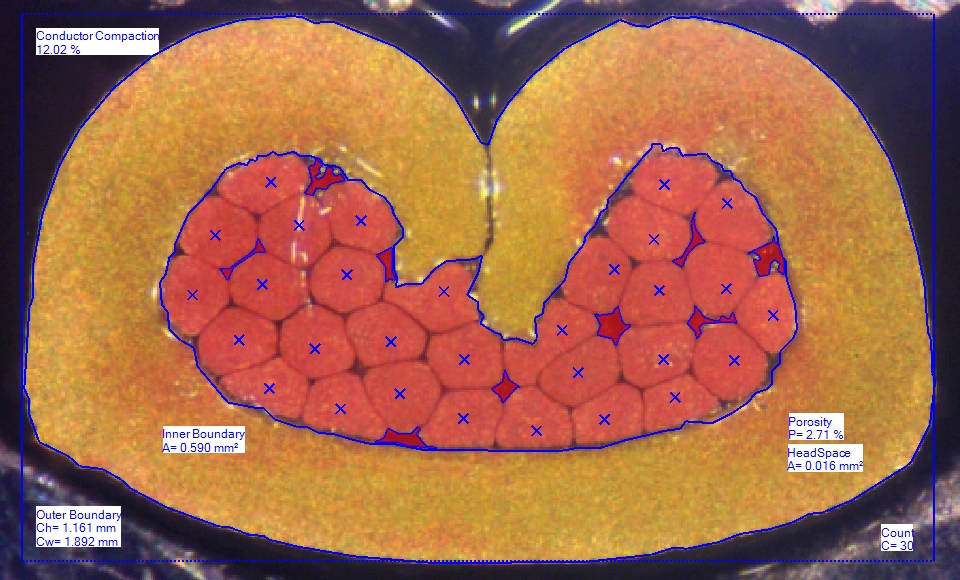

Cross-sectional evaluation of the crimp terminal is being carried out, but it takes time to prepare the sample and its efficiency is poor.

Solving Problems

The Crimp Terminal Cross Section Analysis System does not require any plastic compaction and can cut wires up to the max. 60sq. The cross section and the longitudinal section can also be evaluated. Analysis is performed automatically with the provided software. You can finish from cutting per piece to issuing analysis reports in a few minutes.

Introduced equipment

Other examples of introduction

Industry : Manufacture of automotive harnesses

A non-harmful liquid is needed when performing surface treatment when preparing cross-sectional samples

Industry : Manufacture of automotive harnesses

Measuring the dimensions of the wire peeling length before crimping is needed

Industry : Manufacture of automotive harnesses

A crimp terminal rupture tester that can be pulled at a constant speed is needed

Industry : Production of consumer harnesses

Voluntary inspections by facility operators should be eliminated to save manpower

Industry : Manufacture of automotive harnesses