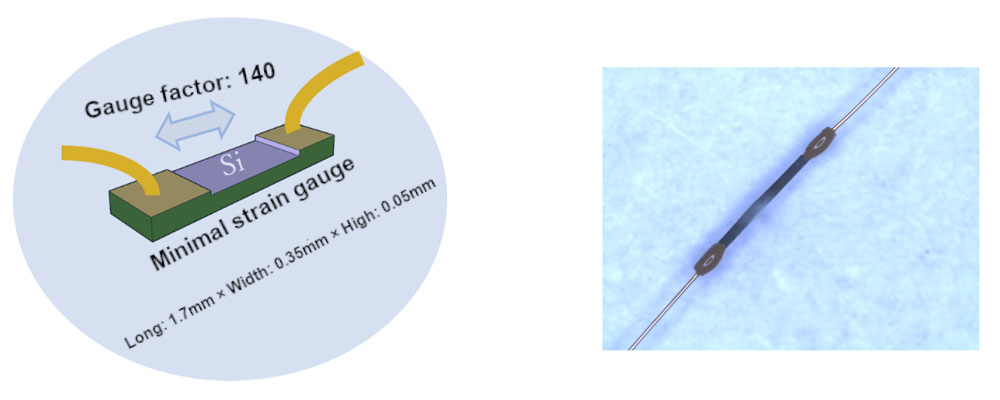

This sensor employs an ultra-minimal semiconductor strain gauge that has a sensitivity of approximately 70 times or more than the gauge factor of the metal foil strain gauge. Semiconductor strain gauges are strain gauges that utilize the piezoresistivity effect, in which the electrical resistivity of semiconductors changes due to stress. Minimum distortion can be measured with high accuracy and high output.

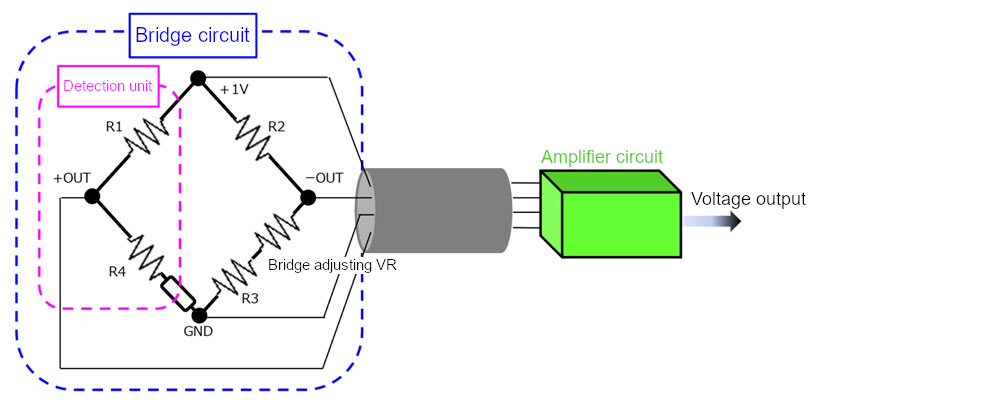

Since the resistance change of the semiconductor strain gauge is very small, it is necessary to construct a Wheatstone bridge circuit as shown in the figure.

When force is applied, adhesive is applied to the strain generating body that generates strain (R1, R4) in the tensile or compressive direction.

When distortion occurs, the electrical resistance value of the gauge changes. This equilibrium condition collapses and a potential difference is generated between the + OUT and-OUT, and the load can be measured from the potential difference.

One M4 screw can be tightened to the specified torque.

0.1 You can see the change in ultra-minimum distortion from μ-distortion.

It is mainly used for monitoring micro-vibrations, etc. that are constantly generated by mounting on structures, etc.

Attach the semiconductor gauge to the shaft of the 8φ bearing. It monitors the tension of the wire flowing through the bearing, allowing you to see cuts, foreign matter, etc. at high output. In this way, sensing becomes possible with almost no change in the existing component design.

Compact pressure gauge with diametral 10mm and height 3mm. It is waterproof and dust-proof, and can be used underwater under specified conditions. Despite its ultra-high sensitivity, the zero-point temperature response is ± 0.05%RO per °C or less. Customization such as size change and specification change to pore water pressure gauge is also available flexibly.

The piezoresistive effect of semiconductors (germanium, polycrystalline silicon, amorphous silicon, silicon carbide, single crystal silicon, etc.) can be several orders of magnitude larger than the geometric effect. This makes it possible to create semiconductor strain gauges with very high sensitivity.

As a weak point, the characteristic change by temperature is big, and the gauge is very small, so handling in manufacturing is very difficult.

We can also develop small sensors with a temperature-change 0.05% RO of ℃ or less at the zero point by clearing this weak point.

We will design distortion-causing parts and attach semiconductor strain gauges according to the object to be measured by the customer, and we will deliver them to the customer in a sensor-oriented condition.

Design and development of sensors using semiconductor strain gauges can be performed by True Soltec.

Contact Form

Contact us by TEL

+81-49-242-9184(Mon - Fri, 9:00am -6:00pm)

Contact us by FAX

+81-49-242-3190

Business Day Calendar

| Sun | Mon | Tue | Wed | Thu | Fri | Sat | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||||||||||||||||||||

| ||||||||||||||||||||

| ||||||||||||||||||||

| ||||||||||||||||||||

| ||||||||||||||||||||

Business holiday